The test dummy

This project started when I was offered a 20 year old nitromethane powered HPI RS4 for 10 dollars. Naturally, I purchased it and began working towards reviving it in my own image. From the start, I decided to use this car as a test bench for ideas and concepts I had either been told would not work -or were outlandish to the point where few others had tried to do so.

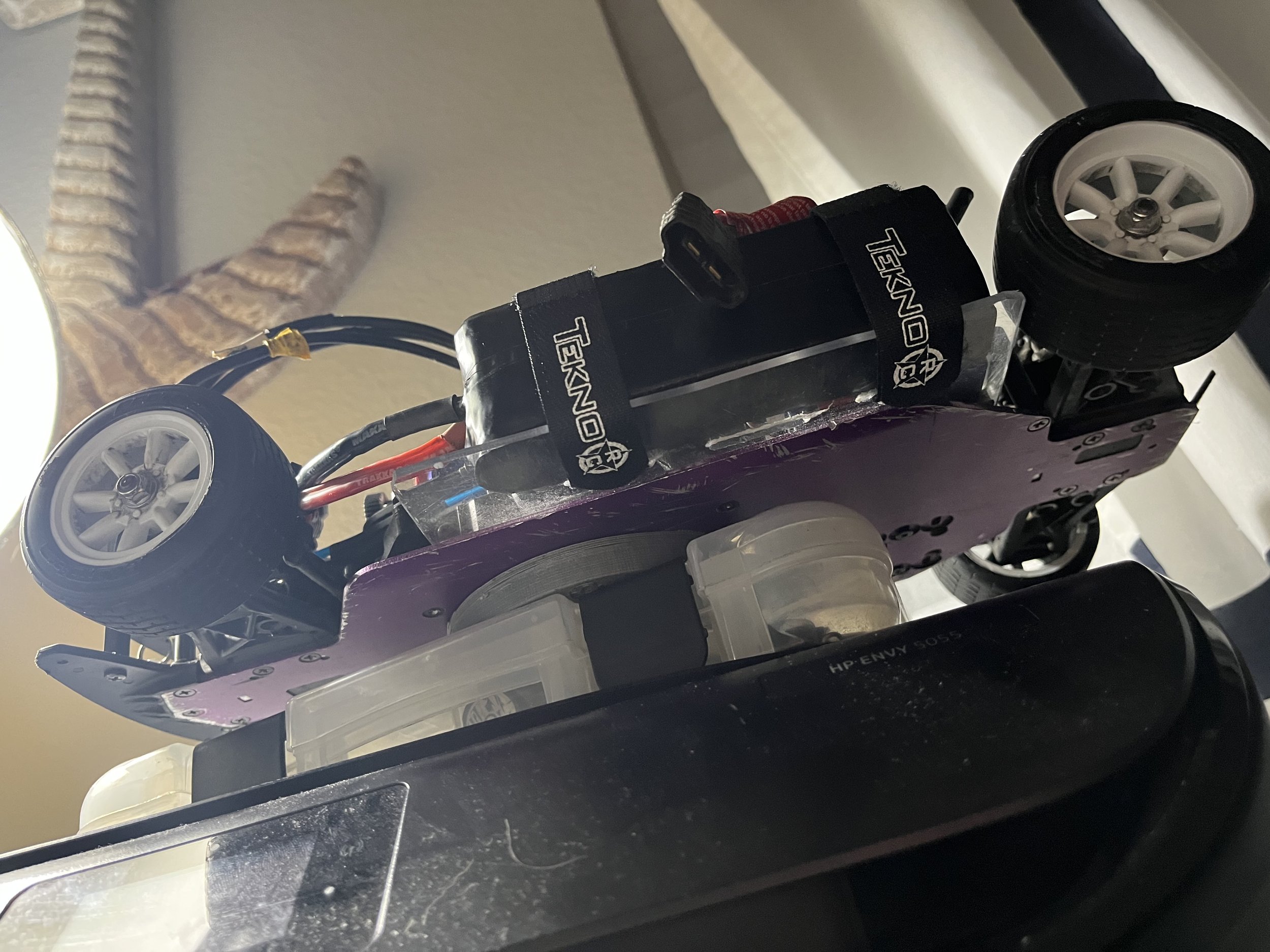

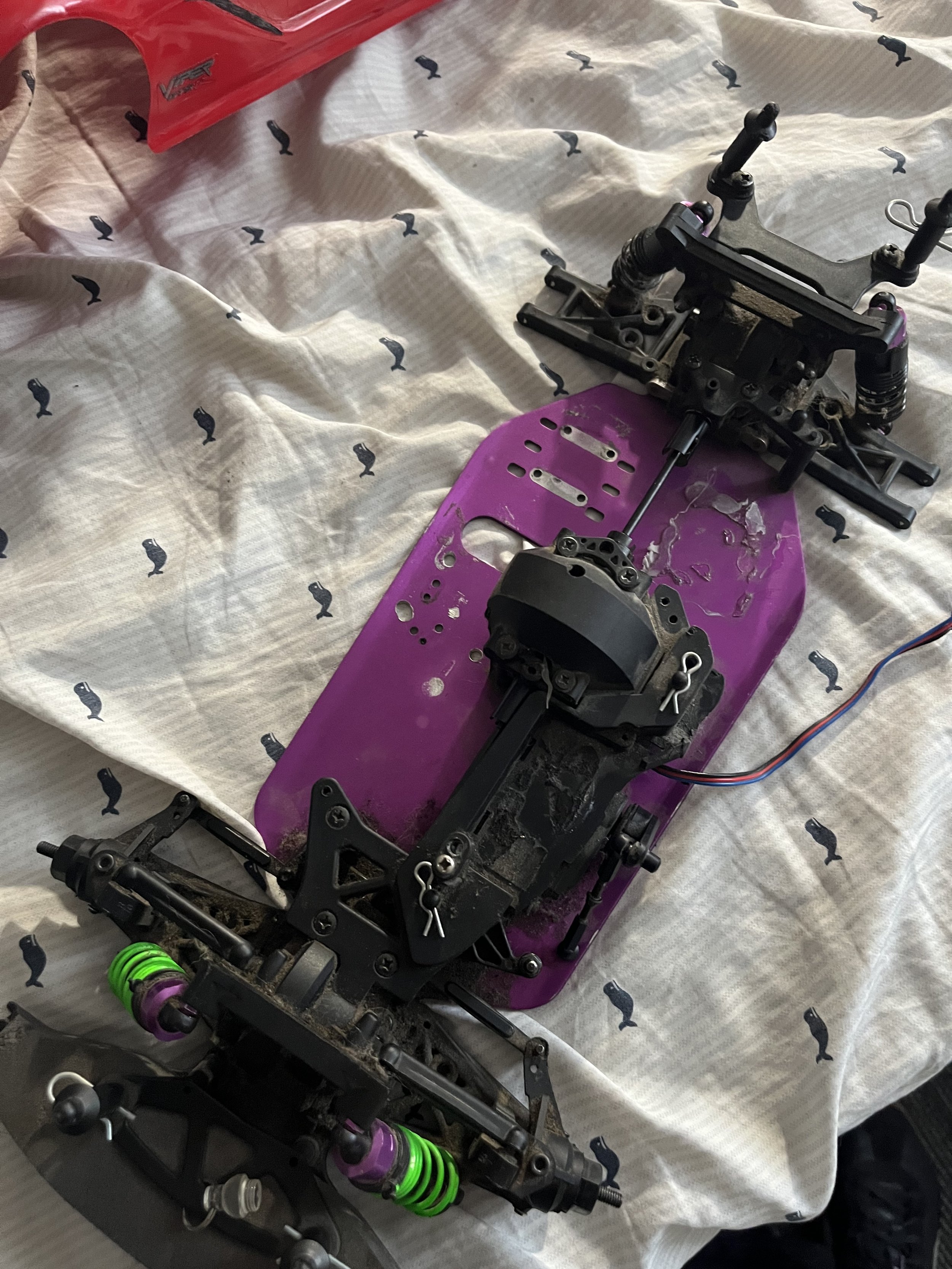

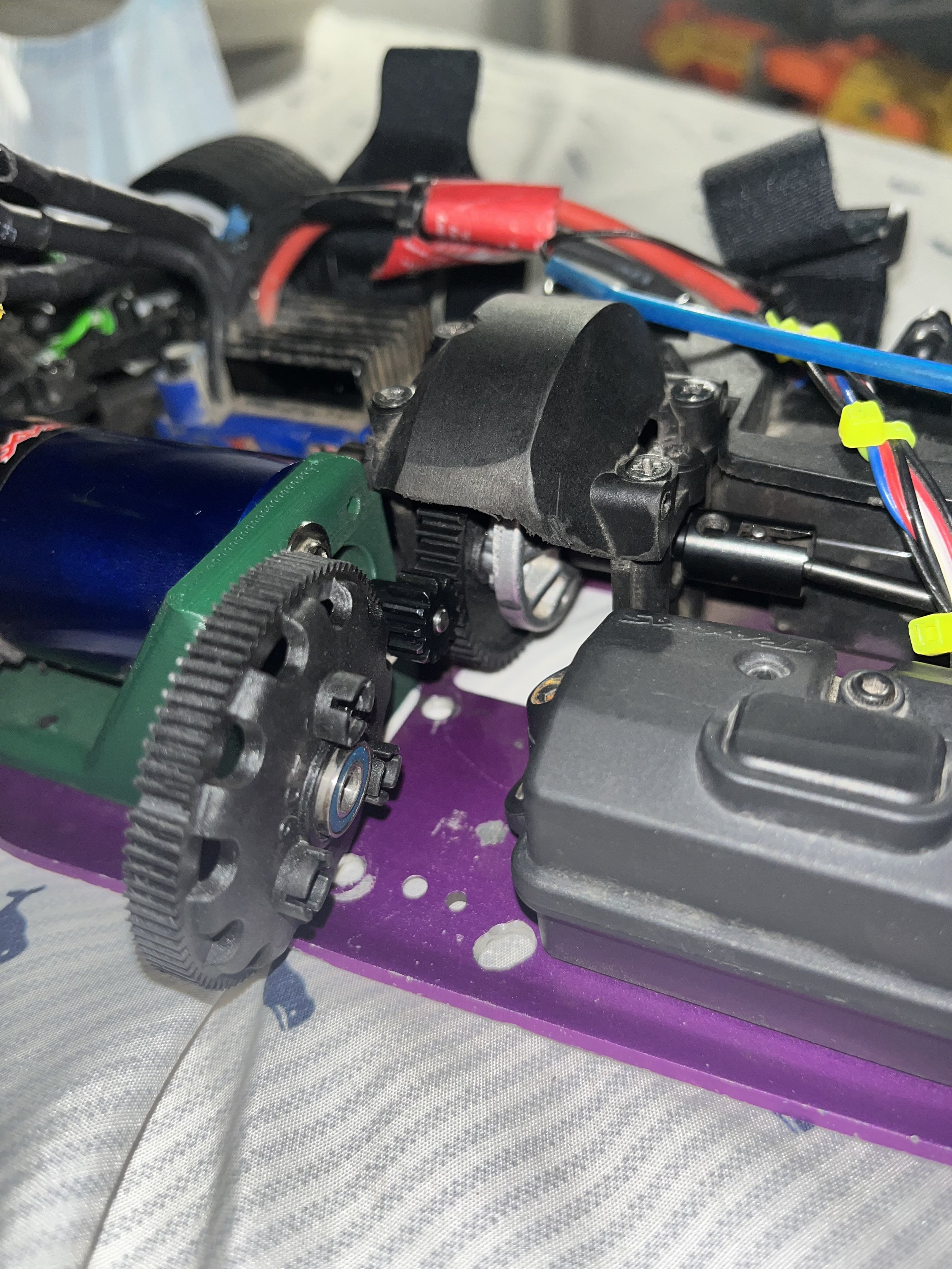

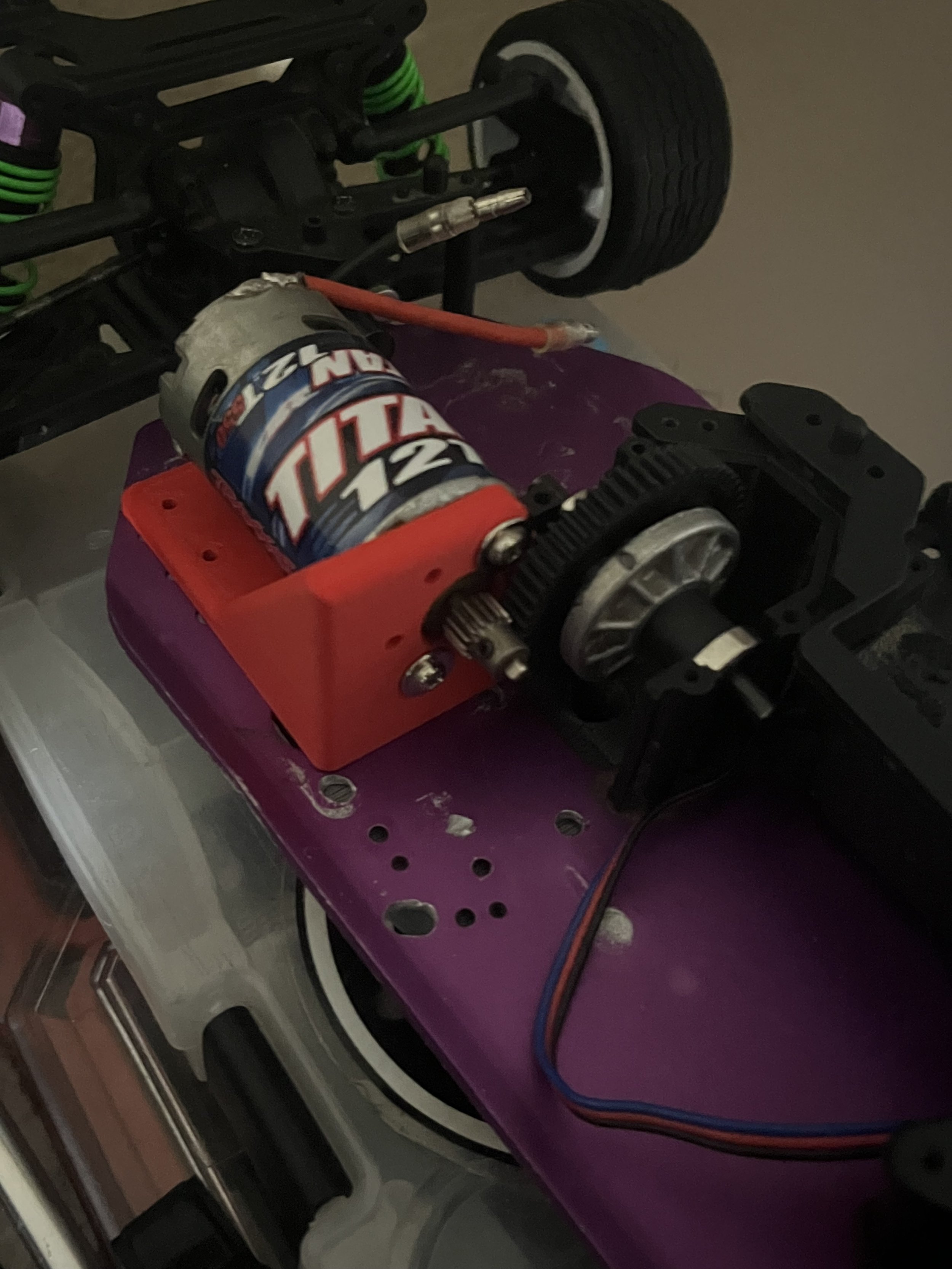

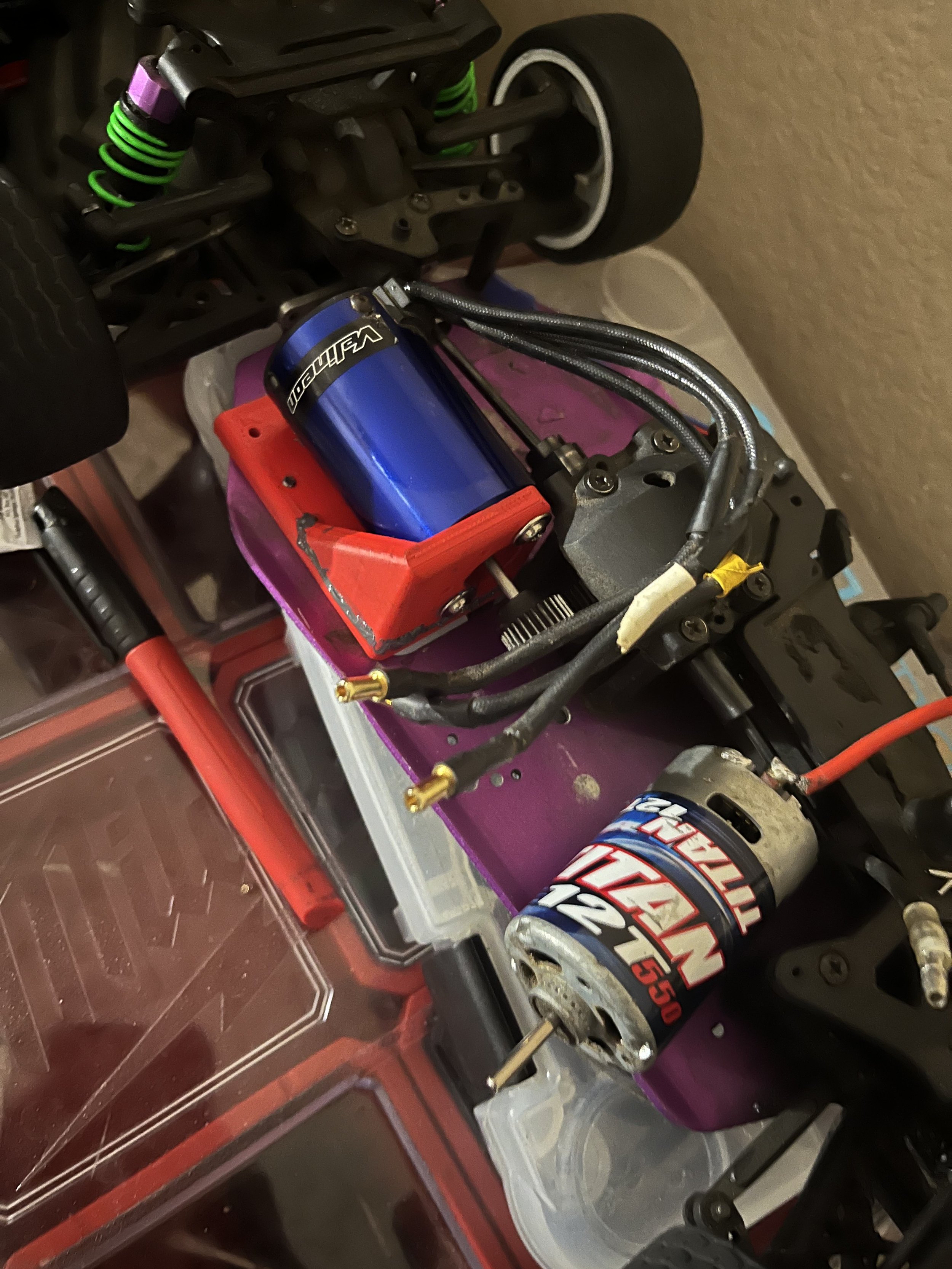

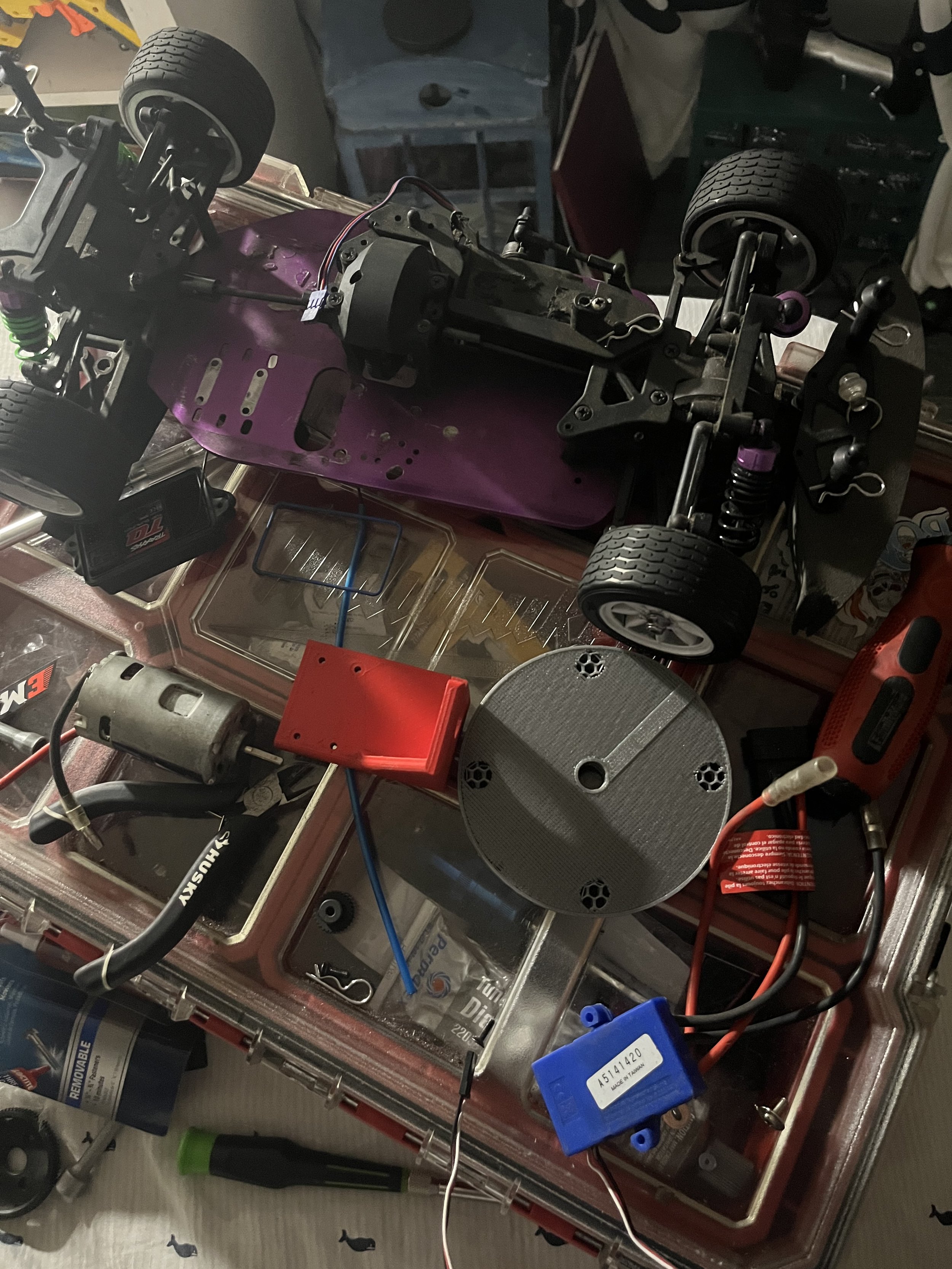

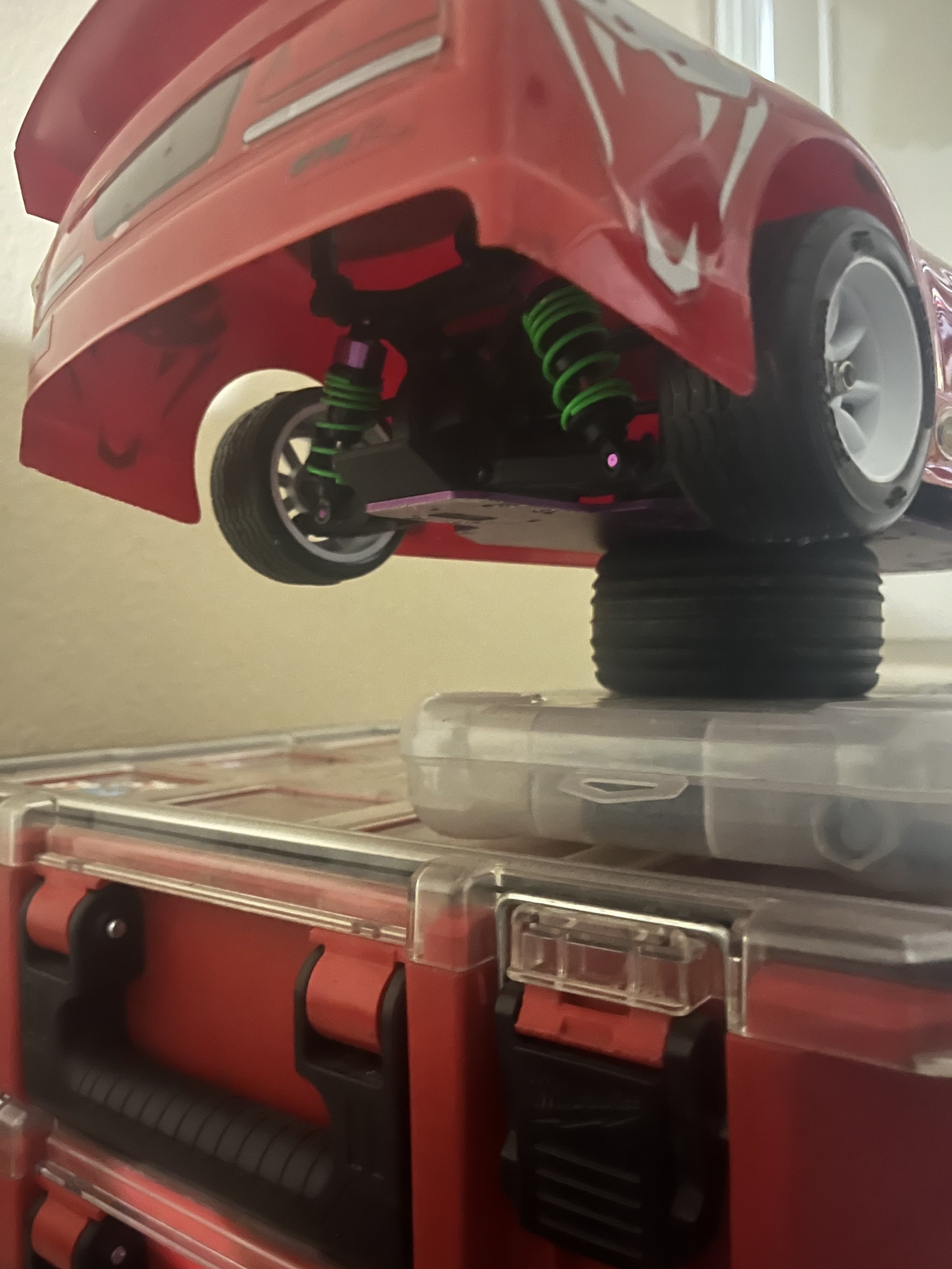

The fact that this car had been out of production for over a decade meant that original parts were scarce and often times ridiculously expensive due to the semi-collectible nature of the model. This forced me to get “creative” in the sense that I combined components from at least 7 different types of vehicles (quadcopter, boat, buggy, etc.) in ways that they were never intended to be used. An example of which would be the slipper clutch unit from a wrecked monster truck becoming my main transmission gear mount (after several painstaking hours with a dremel and drill). Whatever could not be hand-made was either designed and 3D printed, or laser cut at school from polycarbonate sheeting. Electronics were a conglomeration of servos, motors and speed controllers from various manufacturers and intended uses.

A personal idea that I push into everything I engineer is the ability for wear components to be practically replaceable in the event that something destroys itself. This is what made designing a transmission assembly so difficult, as having removable drive/driven gears was not something I had experience with, nor were there any direct aftermarket parts to support myself with.

As mentioned above, this was mainly an inexpensive way to find out what would happen when unorthodox methods were used to approach a result. The final product was an overpowered shaft driven all wheel drive monstrosity with a habit of destroying spur gears (despite never actually being able to properly retain traction on any surface). Despite this, it still had the ability to overtake 40mph race go-karts (assuming the driver was decent). Some takeaways I got were the negatively destructive effects rotating mass has on any assembly, the effects poor weight distribution has on vehicle dynamics (in addition to the painstaking process that comes with dialing in on-road suspension), and the astounding strength epoxy has in torsional applications (this one really surprised me).

In the end, the car destroyed it’s factory differential (sintered aluminum and modern electronic power do not mix well), along with two hardened steel driveshafts (which I never actually found). I assume this was partly due to it’s severe under gearing and my very heavy usage of the throttle. Interestingly enough, none of my fabricated assembly was damaged.

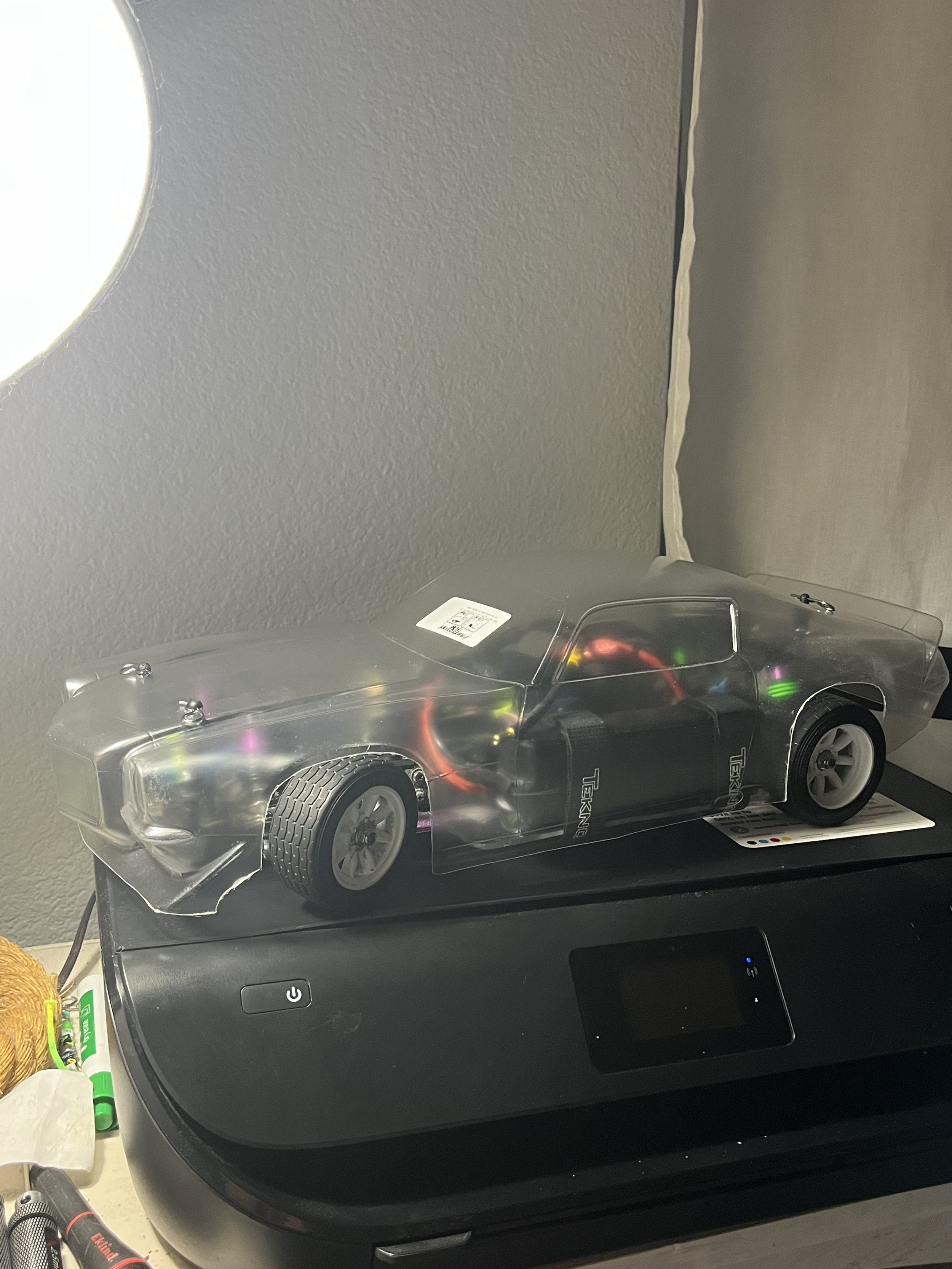

It now resides on a shelf as a reminder of what can be done with a little ingenuity and a lot of random parts.