Modernizing an 80’s Honda Icon

Over the few semesters I have been chipping away at getting an old Honda Fl250 up and running again. I came across the machine on Facebook Marketplace after having the urge to see what these things were selling for.

Upon meeting the seller and inspecting the machine, several things instantly became apparent. The first was that the engine was completely shot to the point of needing a complete teardown, the chassis was slightly tweaked and every single component that could wear out was worn out. I decided to tackle the mess of a machine anyways, mainly because I wanted to force myself to do things that I was not comfortable doing (rebuilding 2 strokes, specialized fabrication, wiring, etc.). At the end of the day, I could have a really fun toy in addition to the skills I’d learn fixing it.

I began by tearing the buggy apart in order to address some of the issues it had such as the rats nest of a wiring harness that some previous owner had created when retrofitting an electric starter motor (which has issues of its own). In addition to this, I found that the engine mounts were completely degraded and the entire car was missing a plethora of hardware on everything ranging from the axle mounts, to the roll bar itself…

Disassembly of the engine

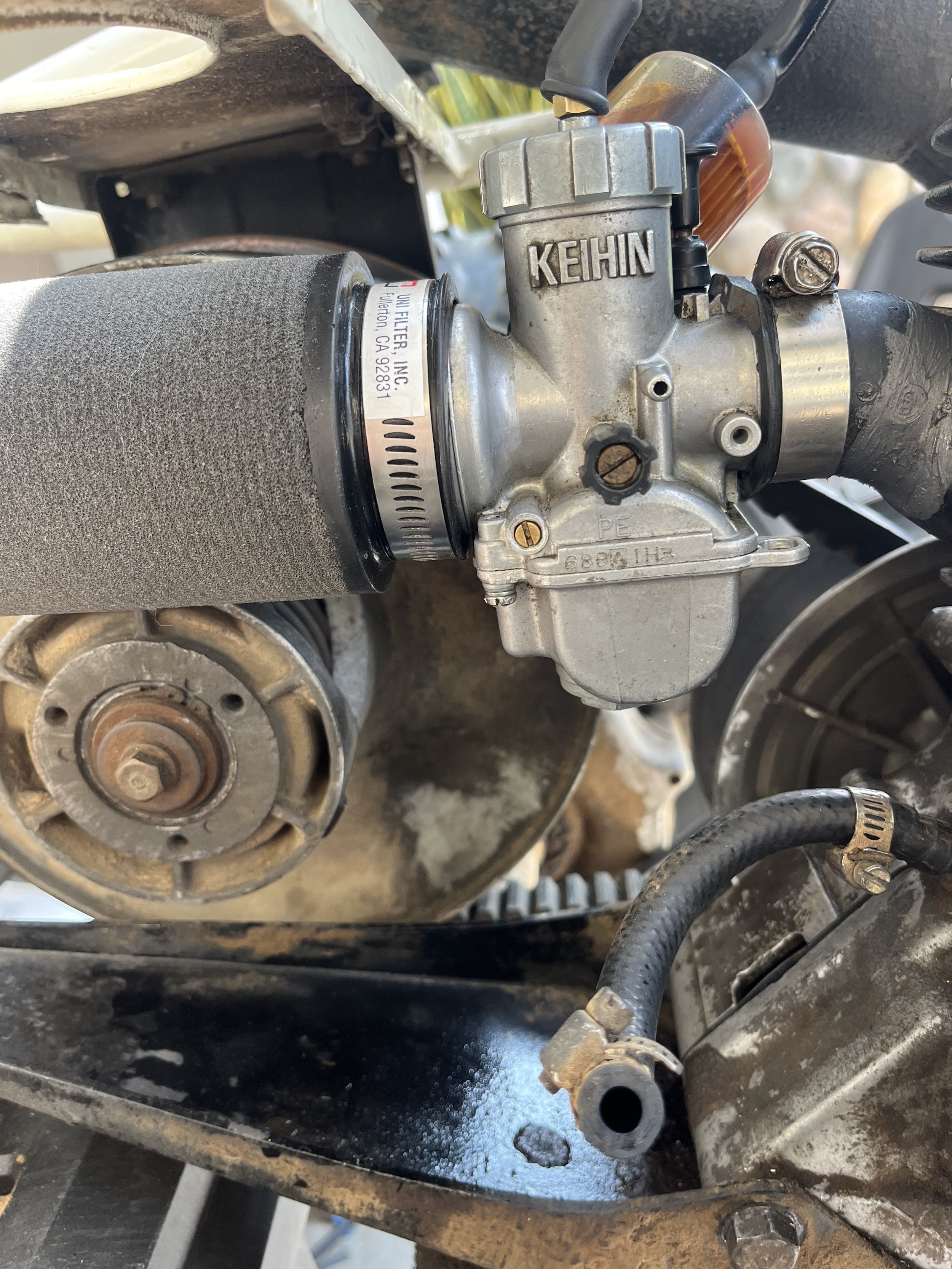

I tasked myself with designing and overseeing the fabrication of a new engine mount which would allow for the installation of a modified off-shelf OHV engine (roughly 11 horsepower). We chose this primarily because budget would not allow for the sourcing (and rebuild) of another original 248cc Honda engine (and all of the necessary components to make it run properly). This was not a simple feat, as the chassis was designed around the intended engine and mount assembly, along with a unique gear reduction unit and axle which we did not have in hand (nor could we justify buying due to cost and the fact that the engine being used had completely different characteristics than that of a high revving two cycle).

Some things I intentionally designed into the new assembly were proper axle clearance, the ability to easily mount different bigger engines (a 570cc Briggs V-Twin is being prepped as of now), and to keep the center of gravity as low as realistically possible (as the roll cage already adds significant weight up top) while packaging everything neatly. Most importantly, it had to be manufacturable in-house by someone other than myself, so simplicity was a big factor in the final product.

Current plans include upgrading/tuning the CVT unit and making the car safety compliant in order to race wheel-wheel with other similarly built vehicles at a local offroad short course race track.